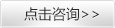

1.配料箱內的粉狀物料因其物理特性,加工粗細度,存放時間長短和料倉底部結構的不同,會發生不同程度的結拱現象,影響配料計量的精確度和配料周期。對此,曾對配料箱底部的結構形式作過多次試驗,如把料倉錐度部分的每一對邊做成對稱的,試驗結果物料存放了數小時后即產生結拱,后又在倉底部安裝減壓帽,結拱雖有改觀,但效果不明顯,最后把倉底做成不對稱形式,這樣就可增大二條短邊倉底的卸料角度。

1.Ingredients box powdered materials because of its physical properties, processing coarseness, storage silos of different duration and bottom structures, different levels of knot arch phenomenon will occur, affecting the accuracy of dosing and dosing cycle. In this regard, the structure had the ingredients at the bottom of the box had several tests, such as the silos taper portion of each of the sides made symmetrical, test results produced materials stored for several hours after the knot arch, and later in the warehouse bottom mounting pressure cap, knot arch although improved, but the effect is not obvious, and finally the warehouse at the end made asymmetrical form, so you can increase the discharge angle between two positions at the end of the short side.

2.電子秤的確定飼料廠的配料計量裝置有容積式與稱重式。前者由于稱量精度較低,現在一般不沿用。后者又分為以杠桿為原理的自動配料秤和傳感器為原理的配料秤。按配料方式計有一料一稱和多料一稱二種。

2 electronic scales to determine the feed mill ingredients have positive displacement metering device and weighing. The former due to lower weighing accuracy, is now generally not in use. The latter is divided by the principle of the lever for the automatic batching scales and sensors for the principle of batching scales. Ingredients way by feeding a meter has a name and a multi-material, said two kinds.

3.微量元素的稱量添加本成套設備不設微量元素的稱量、攪拌,對于配方中的礦物添加劑,維生素,抗菌素等微量添加物,先按照配方的配比再加一定數量的載體混合成預混合飼料并由人工直接放入攪拌機。

3 Add this trace element weighing equipment weighing no trace elements, stirring, for formulation of mineral additives, vitamins, antibiotics and other trace additives, first formulated in accordance with the ratio of plus mixed into a certain number of carriers by artificial pre-mixed feed directly into the mixer.

飼料調料機:http://www.rzguanggaowang.com/